This post contains affiliate links which we are compensated for if a purchase is made. Using links costs you nothing and helps to support the ongoing creation of content. Thank you for using them.

Can Fermentation Occur Too Quickly? If you are searching this question it usually means that the fermentation of the beverage you are making is proceeding at a much fast rate than expected. So is this a problem? Will it affect the flavor and quality of the beverage you are making?

The fermentation stage of alcohol production can proceed too quickly and it will affect the flavor of the final product in most cases except for when the alcohol is distilled where the impurities can be removed during that process. The flavor is affected because there is an increased number of by-products, such as esters and fusel alcohols produced as the reaction increases in speed that can impact the flavor of the end product.

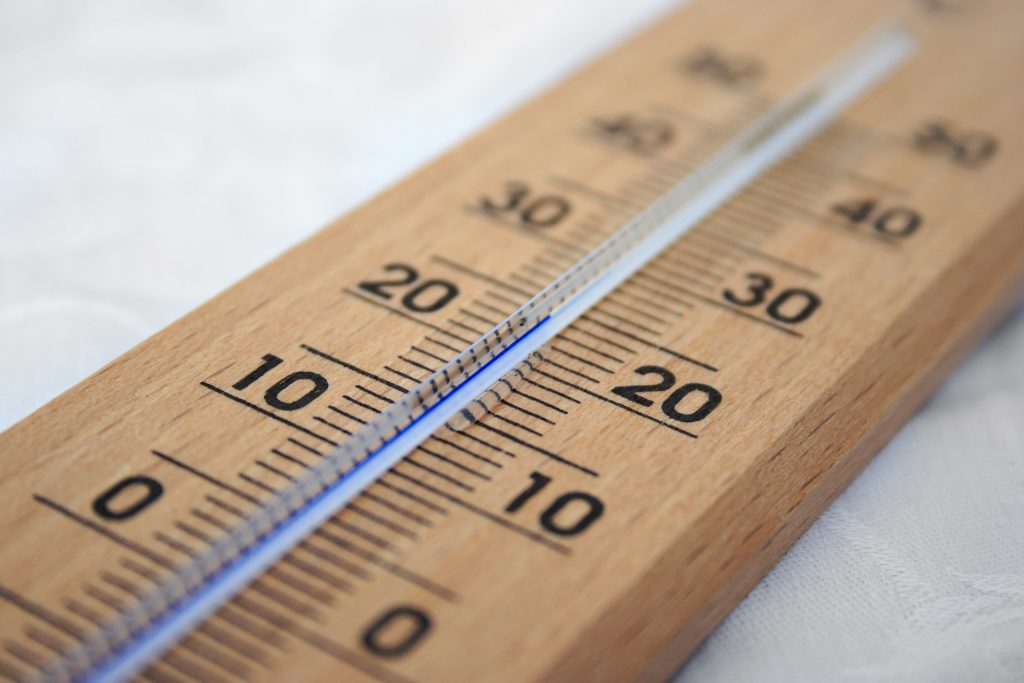

When making products such as beers or ciders it is best that fermentation process more slowly. The speed of the fermentation is best controlled by keeping the temperature around 68°F (20°C). To reach that temperature it is best to add the yeast when the sugar solution is a few degrees below the target fermentation temperature. The reason for this is that the reaction is exothermic and will result in a temperature increase of a few degrees, to read more about this click here.

What Is The Normal Speed That Fermentation Should Proceed?

Beer and Cider Fermentation

In most cases, the fermentation of a 5-gallon brew will take around 1 to 2 weeks depending upon the temperature of the brew irrespective of whether it is a Beer, Cider, or Ginger Beer. This generally occurs when the fermentation is carried out at temperatures around 68°F (20°C) but that can vary depending upon the particular recipe and yeast being used. To read more about this click here.

Wine Fermentation

The wine typically takes 2 to 3 weeks to complete the primary fermentation process, however, wine requires a second fermentation step referred to as secondary fermentation. In the secondary fermentation process, the wine is separated from the yeast sediment produced from the first stage of fermentation and stored in a clean vessel. It is allowed to sit at least three months to a year.

Generally, the secondary fermentation process is a much slower process by its nature where the reactions slowly consume the byproducts produced in the initial fermentation stage. Secondary fermentation is also sometimes used in the production of beer, to read more about this click here.

Fermentation For Distillation Of Spirits

The primary fermentation for the production of spirits usually takes between 7 to 10 days to complete but can be completed in as little as 3 days if specific high-speed yeast strains are used. These strains of yeast are discussed in the section below.

What Impacts The Speed Of Fermentation?

There are several factors that impact the speed of Fermentation which include the Temperature, the Type of Yeast, and to a far less degree the type of beverage. Beers with higher specific gravities tend to take a little longer to ferment.

Temperature

The single largest factor that influences the rate of fermentation is the temperature. Increasing the temperature increases the reaction rate of the fermentor. There are numerous studies over the years looking at the rate of fermentation which is tracked by the production of carbon dioxide production. The 1965 study by N. Merritt is a good example of a quantitative study that shows clearly the degree of influence temperature has upon the activity of yeast. The graph shown below demonstrates that a change from 25°C to 35°C (77°F to 95°F) will have a 3 fold increase in the rate of carbon dioxide production.

Type Of Yeast

There are a number of different yeasts that available on the market which include baker’s yeast, different types of beer yeasts, wine yeasts, and specialty yeasts such as turbo yeast. Many of the yeasts are designed to do specific jobs and will have different rates of reactions and will also produce different byproducts that will affect both the flavor and the rate of reaction.

For example, beer yeasts are generally categorized into two main groups, Ale and Lager. Ale yeasts prefer warm temperatures around 60-70°F (18-20°C) and will become dormant at around 55°F (12°C), whereas lager yeasts operate at lower temperatures of around 45 to 55 °F (7 to 13 °C). However, Lager yeast has been known to be used at high temperatures to create a fruitier beer as a result of the increased byproducts.

Another widely used variant is turbo yeast, which is designed specifically to produce alcohol extremely quickly, within one or two days. Turbo yeasts are specifically designed for producing spirits. The turbo yeast products are not suitable for directly fermented drinks such as beer. There have been a number of reports on online forms of brewers attempting to use this type of yeast to brew beer, they have generally found that it imparts a bitter flavor which has occurred as a result of the production of increased byproducts and the use of a lot of nutrients.